A versatile, flexible, energy-saving, independent, and environmentally save solution, that is the new ECOFEEDER concept by eco-e (eco-eag.com) and Clesid Lorber (clesid.com).

The traditional melt shop needs a marginal modification to turn out to be an energy saving, environmentally friendly and long-lasting enterprise, an enterprise which can easily look forward to the year 2050 and further.

Your electric arc furnace is ok. There are no big changes needed. However, a small and easy to handle modification would help to reduce losses, decrease vulnerability of side and roof panels against heat impact and damage and reduce considerably the electrode consumption. This small modification consists of a new off-gas draft.

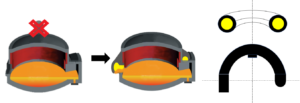

The secret is simple: Add a half-torus from EBT to the slag door, same side as the 4th hole, take the 4th hole off and connect the torus to the combustion chamber. With this modification you clear out all issues at the slag door (close-open, false air) in the furnace (cold spots) and excessive heat loss (through the 4th hole) which charges the energetic system. With the modification you win, you reduce energy input, you reduce burner power to heat the cold spots, you reduce electrode consumption – and the best is you don’t need to change your furnace, you can switch from your old 4th hole system to the new torus system with little manipulation – one shift change, you replace the roof without 4th hole with the spare with 4th hole, you change the closure at the combustion chamber (same size) and you lift off the torus and replace the slag door – that’s it. With that you control the benefits at no risk.

Once this step made – you have also made the first step to a successful scrap preheating system, because the scrap in the furnace equipped with a torus provide you with an effective scrap preheating system inside the furnace.

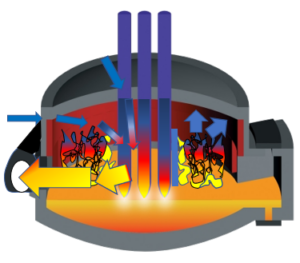

The new off-gas flow passes above the interface steel bath and scrap which has four positive effects: it supports the melting of the scrap just above the steel bath, the pasty surface of the scrap picks up the dust and the cold air intakes are not mixing with the off-gas which has an effect on the off-gas measurement, and to round up the benefits: the ‘colder’ scrap on top of the scrap pile protects the panels.

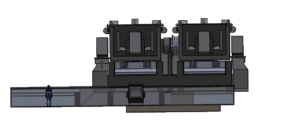

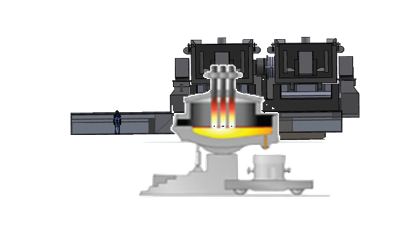

Once you have adopted this clever in-furnace system you will proceed to the next step – the effective use of the off gas of your furnace. As said, the furnace doesn’t need to change – the scrap preheating system, which brings hot scrap in the centre of the furnace (no balcony of eccentric furnace needed) consist of two containers built like a tundish with a cover.

In the first container the hot off gas and the final combustion of CO heats up the scrap. This ignites the pollutions contained in the scrap.

Between the two containers a burner chamber heats up the off gas to a point where the combustion products are burnt. The then clean off gas flows to the second container where is cools down by heating up the scrap there-in.

At the end of the scrap preheating system, a clean and dust-free off gas is available for further use.

The advantages of this 3-level preheating are multiple. Scrap preheating and storage, energy saving, conserving your installation, environmental friendliness, use and repair (preheating container), easy to install, almost no production interrupt, no new buildings (to be verified by a study), lowest CO2 emissions possible, etc.

To initiate and support the efforts to combat the climate change we offer an extraordinary discount of 15% on the finally negotiated sales price for orders until end of 2022.

Recent Comments